S-5! Assists in the Largest Single Rooftop PV Install in North America

Toys"R"Us, Flanders. NJ

Project Details

- Architect

- Advanced Green Technologies

- Location

- Toys"R"Us, Flanders. NJ

- Size

- 5.38 MW

- Cost

- Savings of $366,000 Annually in Energy Costs

SITUATION

In an effort to reduce electricity costs and carbon emissions, Toys”R”Us, Inc., together with Constellation Energy Group, turned to Advanced Green Technologies (AGT) to install a solar photovoltaic (PV) system at their distribution center in Flanders, NJ.

RESULTS

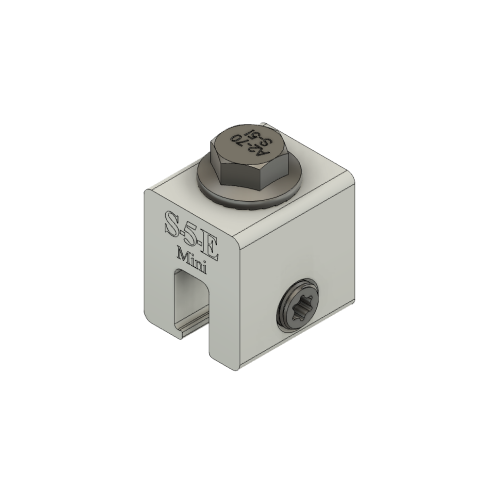

Through the use of S-5!® non-penetrating S-5-E Mini clamps, AGT was able to easily install the solar PV system while maintaining the roof’s weather-tightness and preserving the roof panel manufacturer’s warranty.

STATS

Project size = 5.38 MW

37,144 rigid thin-film PV modules were used

The panels will provide up to 72% of the electricity needed to run the distribution center

90,000 S-5-E Mini clamps were used in the installation

Savings of $366,000 per year in energy costs

Carbon emission reduction of 4,000 metric tons per year

Completed solar array qualified Toys “R” Us to receive 7,500 Green-e® certified renewable energy certificates (RECs) over 3 years

“We chose S-5!® because it is the only product on the market that could be used to secure our custom PV mounting solution to a Butler Seam roof. They are easy to install, helping us reduce installation time.” -Michael Kornahrens, President, AGT

Looking for Solutions

In an effort to reduce electricity costs and carbon emissions, Toys“R”Us, together with Constellation Energy Group, chose Advanced Green Technologies (AGT) to install a solar photovoltaic (PV) system on their distribution center in Flanders, NJ. Prior to the installation of the system, the distribution center used an average of 8 million kilowatt hours (kWh) of electricity and produced an annual carbon emission of 4,000 metric tons, resulting in more than $500,000 per year in energy costs. AGT turned to S-5!® because they were unwilling to compromise the pre-existing roof warranty.

What Worked?

Through the use of 90,000 S-5-E Mini clamps, AGT was able to install 37,144 rigid thin-film PV modules while maintaining the roof’s integrity and preserving the roof manufacturer’s warranty. The completed solar array covers more than 70% of the 1 million sq. ft. standing seam roof, thus making it at completion the largest single rooftop installation in North America. What’s more, the ease-of-use of the S-5-E Mini clamps helped to streamline the installation process, saving time and labor costs.

Long-Term Outlook

The completed PV array will provide 72% of the electricity needed to run the distribution center. This equates to an average savings of $366,000 in energy costs per year ($7 million over 20 years). In addition, the distribution center has reduced carbon emissions by more than 4,000 metric tons per year (80,000 metric tons over 20 years). The array has also qualified Toys “R” Us to receive 7,500 Green-e® certified renewable energy certificates (RECs) over 3 years.

Around the globe, the concept of combining photovoltaic arrays with standing seam metal roofing is growing, and for good reason. A standing seam metal roof has a life expectancy consistent with that of PV modules. A 30-year power source on a 40-year roof, coupled with S-5!’s attachment technology, creates the most sustainable roof systems available today.