Fire Rated Wiring System

Protect Critical Circuits In Case Of Fire

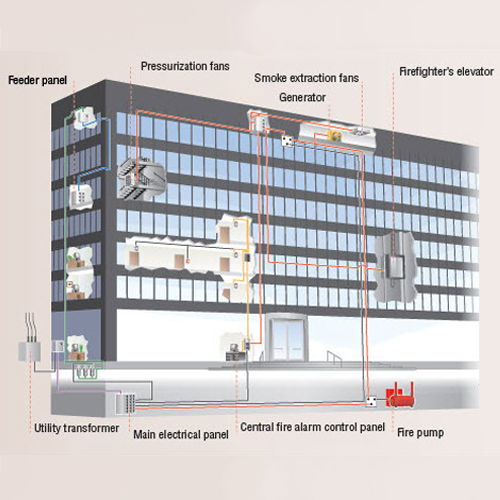

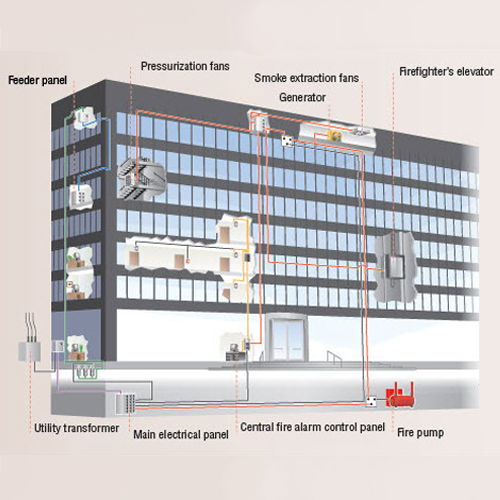

- Worldwide regulations require fire protection for emergency feeder circuits in commercial buildings, public spaces, hospitals, industrial plants and refineries. Critical equipment and processes must continue to operate during an emergency to minimize damage and protect lives.

- Setting the Standard in Fire Safety.

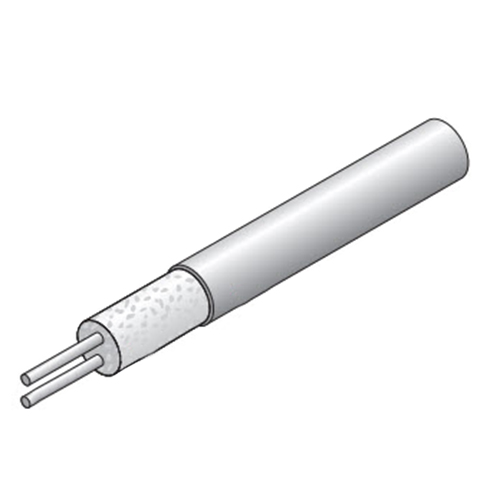

- Historically, fire safety of critical circuits was achieved by running conventional cables behind a heat barrier such as a gypsum board or hollow concrete block; or by embedding the conductors in concrete. Pyrotenax mineral insulated fire-rated cables are UL listed and can withstand temperatures up to 1850°F (1010°C) for two hours. This built-in fire resistance provides greater protection as opposed to the fire-rating of conventional cables which require heat barrier systems.

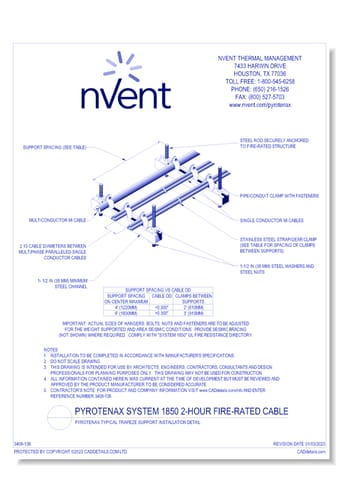

1.

Pyrotenax - Typical Trapeze Support Installation Detail

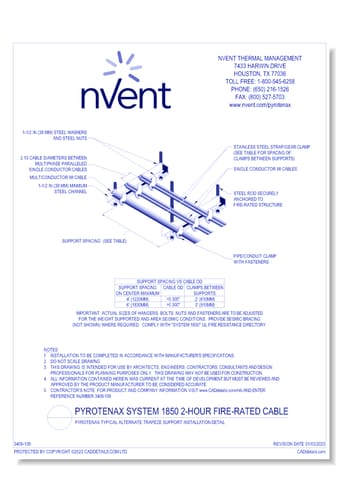

2.

Pyrotenax - Typical Alternate Trapeze Support Installation Detail

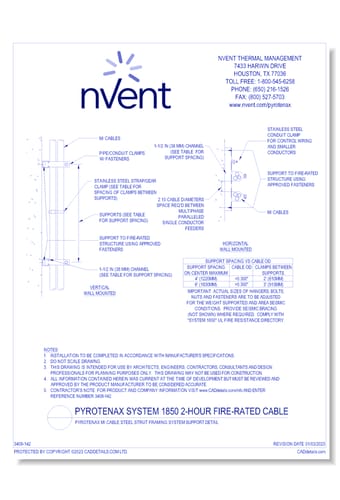

3.

Pyrotenax - MI Cable Steel Strut Framing System Support Detail

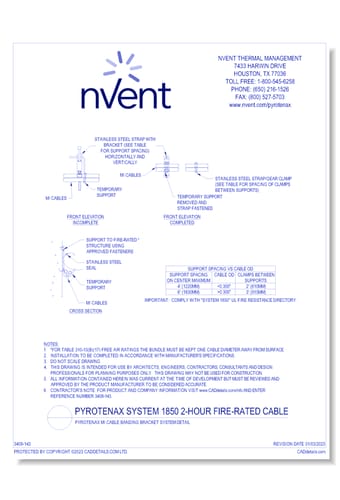

4.

Pyrotenax - MI Cable Banding Bracket System Detail

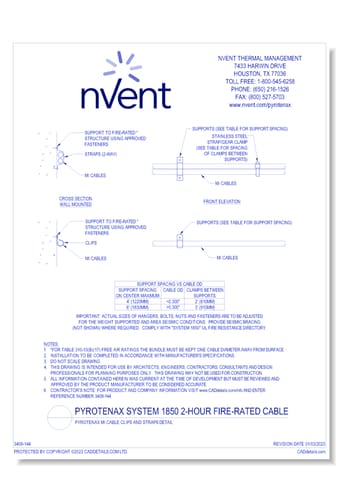

5.

Pyrotenax - MI Cable Clips and Straps Detail

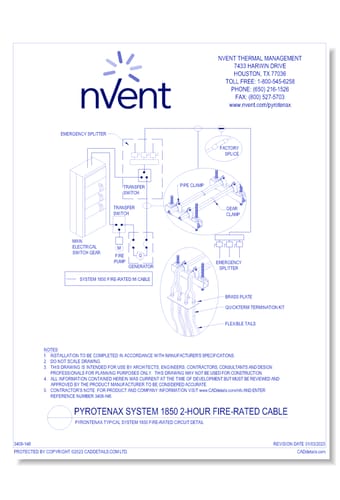

6.

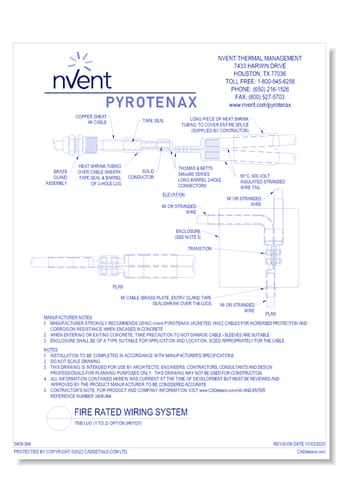

Pyrotenax - Typical System 1850 Fire-Rated Circuit Detail

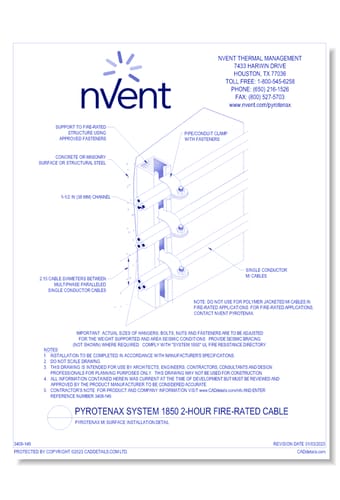

7.

Pyrotenax - MI Surface Installation Detail

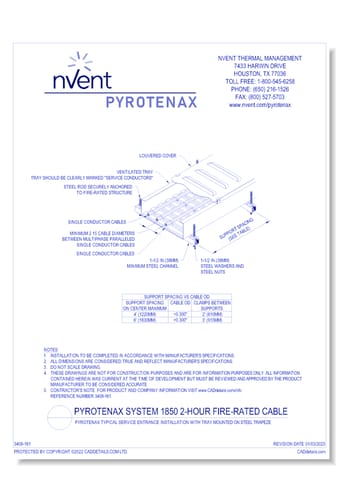

8.

Pyrotenax - Typical Service Entrance Installation With Tray Mounted On Steel Trapeze

9.

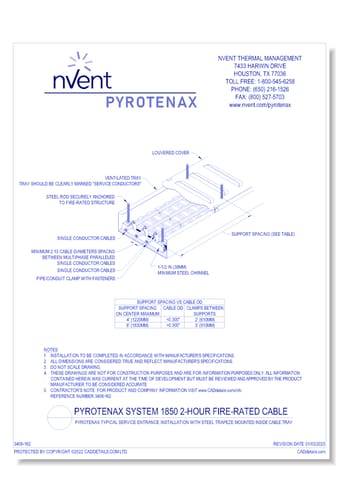

Pyrotenax - Typical Service Entrance Installation With Steel Trapeze Mounted Inside Cable Tray

10.

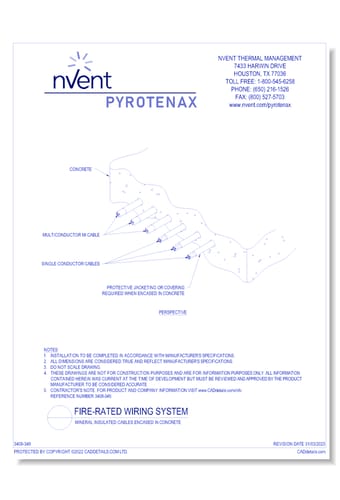

Pyrotenax - Mineral Insulated Cables Encased in Concrete

11.

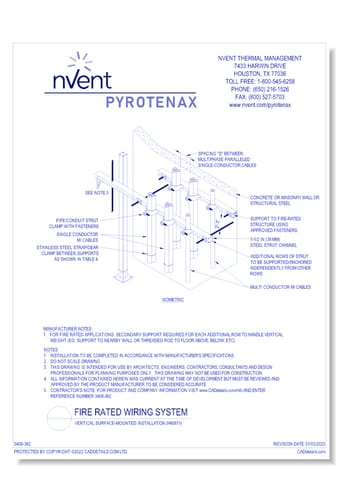

Pyrotenax - Vertical Surface-Mounted Installation (H60811)

12.

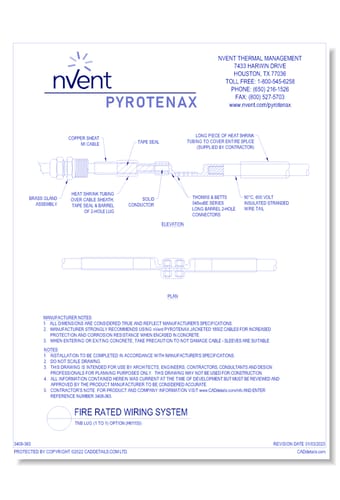

Pyrotenax - TnB Lug (1 to 1) Option (H61155)

13.

Pyrotenax - TnB Lug (1 to 2) Option (H61157)

14.

Pyrotenax - System 1850 2-Hour Fire-Rated Cable Specification (US)

15.

Pyrotenax - System 1850 2-Hour Fire-Rated Cable Specification (CAN)

16.

Pyrotenax - MI Tools

17.

Pyrotenax - MI Accessories

18.

Pyrotenax - MI Terminations

19.

Pyrotenax - MI Splices

20.

Pyrotenax - System 1850 Cable