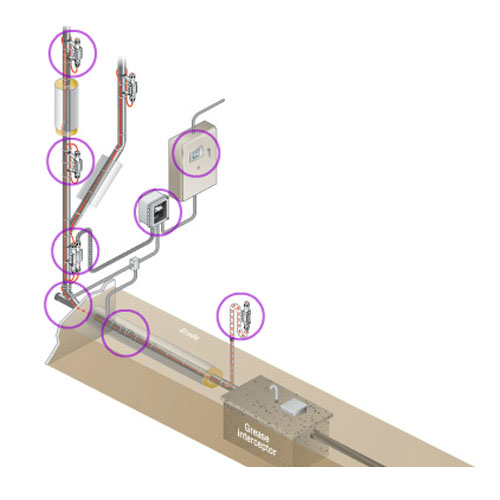

Grease Waste Flow Maintenance

- A grease-line flow maintenance system is designed to maintain a 110°F (43°C) fluid temperature to keep the Fat, Oil, Grease mixture (FOG) in suspension from the kitchen to the grease interceptor.

- Typical applications include piping used for the disposal of waste oils and fats created in the cooking process.

- Typical applications include greasy waste lines from commercial restaurants pre-wash stations and floor drains.

- These drains must exit the building to an exterior grease trap, and must kept at temperature the entire distance to keep the FOG from concealing.

1.

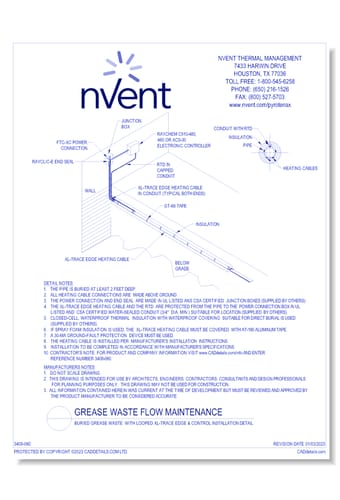

Raychem - Buried Grease Waste Line with Looped XL-Trace Edge & Control Installation Detail

2.

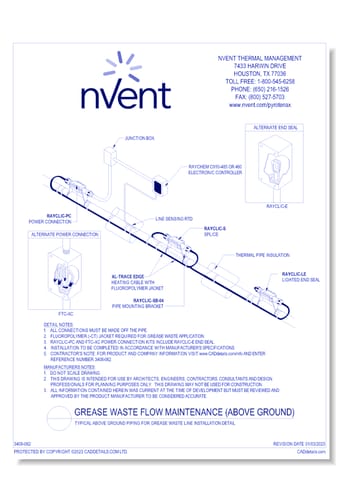

Raychem - Typical Above Ground Piping for Grease Waste Line Installation Detail

3.

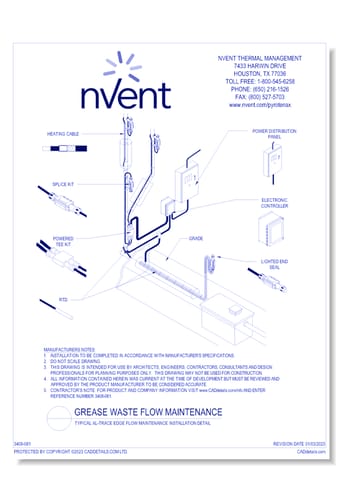

Raychem - Typical XL-Trace Edge Flow Maintenance Installation Detail

4.

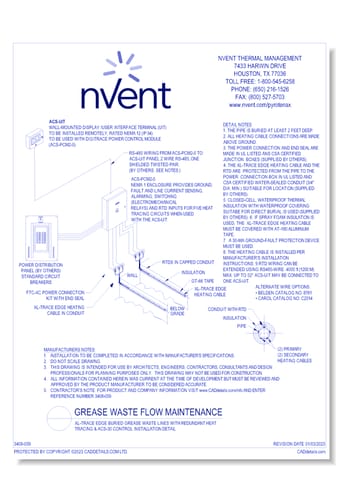

Raychem - XL-Trace Edge Buried Grease Waste Lines with Redundant Heat Tracing & ACCS30 Control Installation Detail

5.

Raychem - H59868 - Specification Section 22 05 33 - XL-Trace Edge for Plumbing Piping

6.

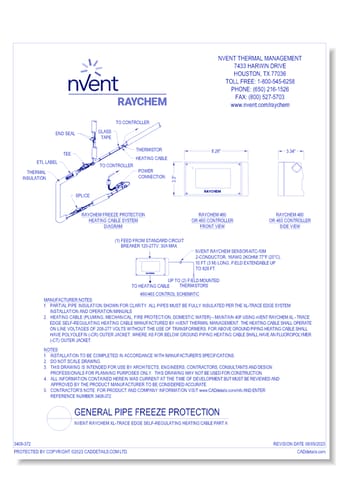

Raychem - XL-Trace Edge Self-Regulating Heating Cable Part A

7.

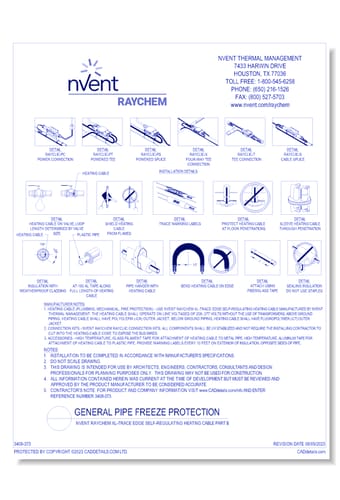

Raychem - XL-Trace Edge Self-Regulating Heating Cable Part B